All-in-one services

Strive for diversity for the globe

Commercial Project

Done in Malaysia

Outdoor Project

Best solutions

Your Professional LED Lighting Manufacturer

Make your project quality and attractive!

Flexible pricing options

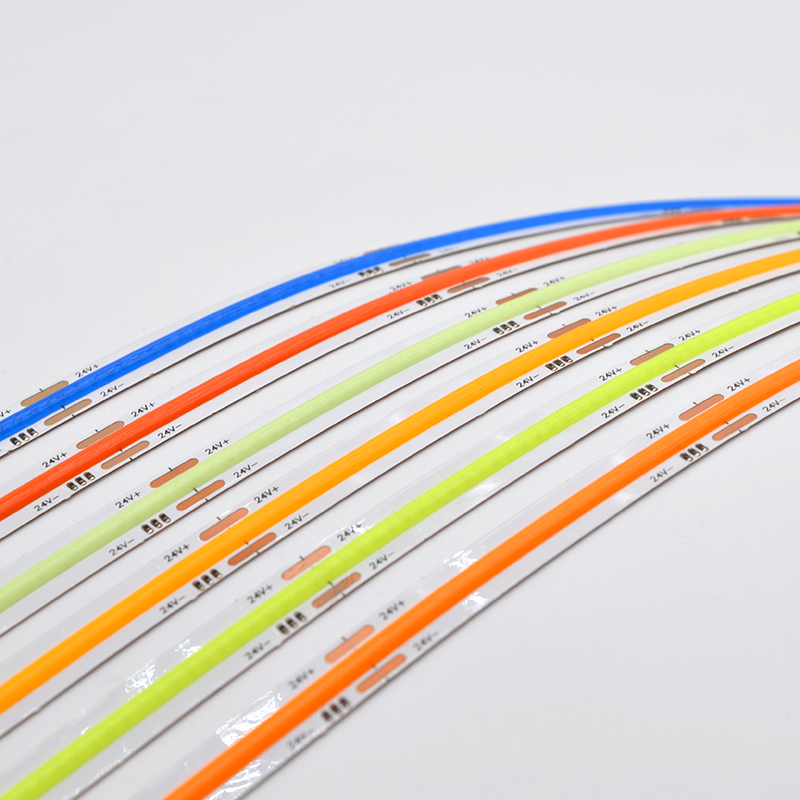

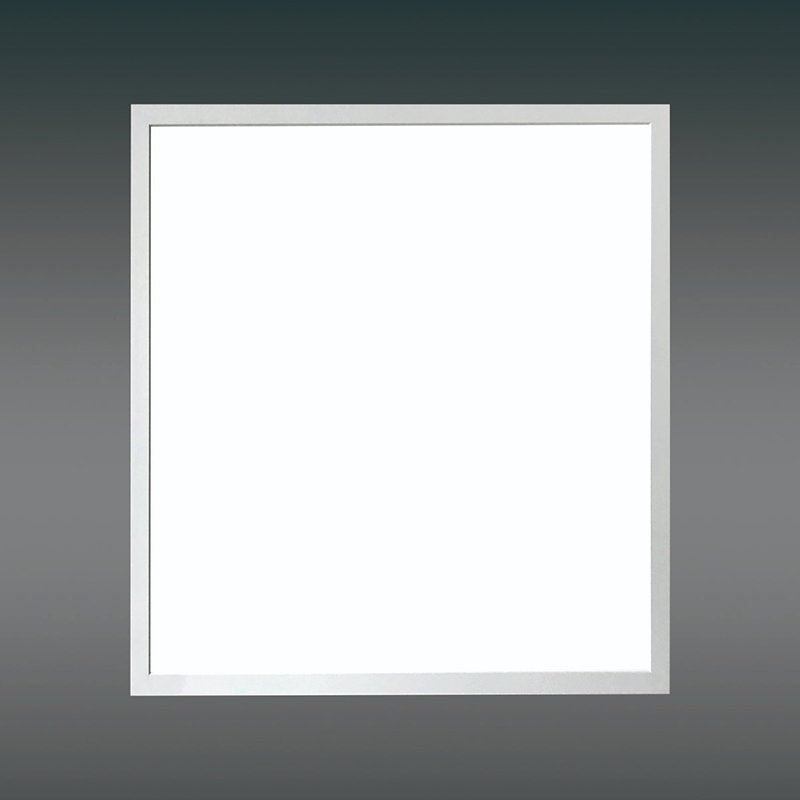

Hotselling Products

Partners with 10+ Brand companies across the globe

Resources

Sign up and Get our Catalogue Dowload. In this catalogue, You will learn: