COB LED Strips 101: Your Comprehensive Guide

COB LED strip Light technology represents a significant improvement in the lighting industry, bringing revolutionary changes to modern Linear lighting solutions. This innovative lighting method not only enhances efficiency and performance but also offers designers and consumers unprecedented creative possibilities. This article will delve into the features, advantages, and disadvantages of COB LED strips, along with installation tips, key considerations, application scenarios, and future trends.

Table of Contents

What is COB LED Strips?

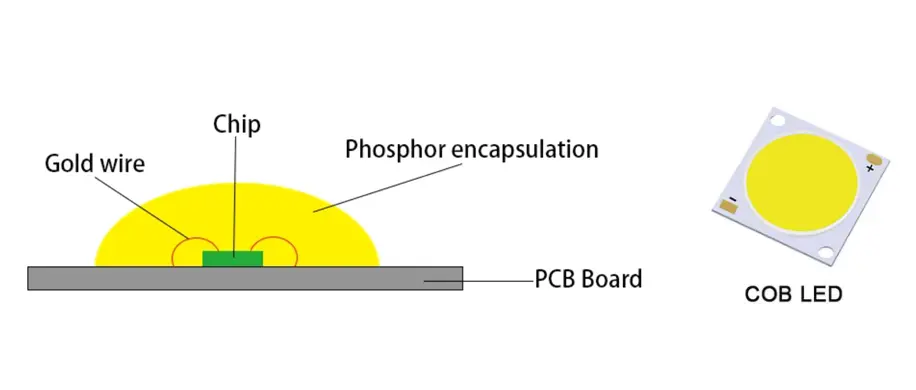

COB or Chip on Board refers to the technology where LED chips are directly mounted onto a PCB (Printed Circuit Board). COB LED Strip lights utilize this technology to encapsulate multiple LED chips directly onto FPC. Typically, the COB LED chips use flip-chip technology . and the phosphor coating applied directly onto the chips. The light emitted by the chips interacts with the encapsulation resin through refraction, reflection, and interaction with the phosphor, producing a uniform emission of light in various colors and color temperatures.

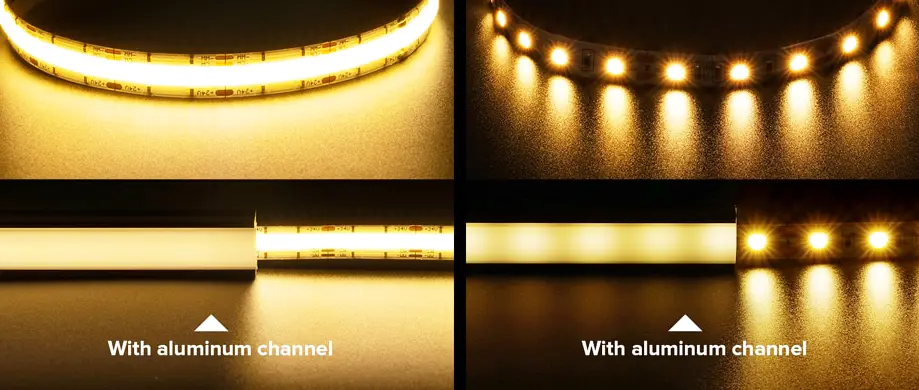

The core of COB technology lies in its highly integrated design. By incorporating a large number of LED chips in a smaller area, COB LED strips achieve higher light density and more uniform light output. This method is fundamentally different from traditional SMD (Surface Mounted Device) LED technology, which typically uses individually packaged LED diodes.

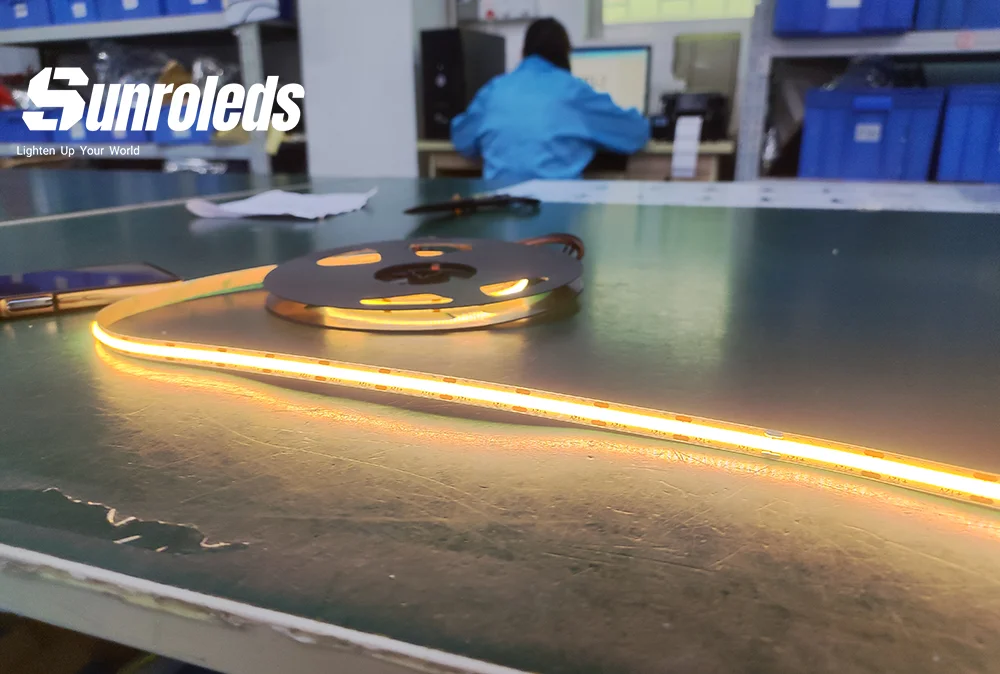

This COB LED Technology have the strip smooth, seamless, and continuous light with Dot Free.

What Makes COB LED Strip Technology Unique?

Chip on Board

COB LED strips use innovative “Chip on Board” technology, where LED chips are directly connected to the flexible printed circuit board (FPCB) without the need for gold wire encapsulation, unlike traditional SMD LEDs. This design greatly enhances the reliability of the strip, as the gold wire is a common potential failure point in traditional LED strips.

Innovative Circuit PCB Design

The PCB design of COB strips are different from traditional SMD LED Strips’. It adopt a unique method: three chips are first connected in parallel to form a group, and these groups are then connected in series to create a continuous strip. This configuration ensures that even if one or two chips in a group fail, the rest of the strip remains lit, significantly improving the overall reliability and lifespan of the LED strip light.

High Density

COB LED Tapes feature a very high chip density, with up to 480 chips and more per meter. This high-density design not only ensures uniform light output but also enhances the overall performance and reliability of the strip. Even if individual chips fail, they do not significantly affect the overall effect of the light strip.

Anti-Static and Corrosion-Resistant Design

COB LED strips typically have stronger anti-static capabilities, which is especially important in dry climates or certain seasons. Additionally, many COB LED strips are designed with corrosion-resistant materials, effectively resisting the sulfidation process and extending the lifespan of the strip in harsh environments.

What Are Its Advantages?

Seamless Design

COB LED Strip Lighting could produce smooth and continuous light due

Energy Saving and Longer Lifespan

Despite the COB Strip’s high brightness and high density,their advanced technology enables them to saving more energy compared to traditional lighting solutions. This high energy efficiency not only reduces operational costs but also meets the modern demand for eco-friendly, energy-saving options. High-quality COB LED strips can achieve light efficacy of more than 100 Lm/W. This combination of durability and low energy consumption makes COB LED strips a cost-effective and sustainable lighting choice.

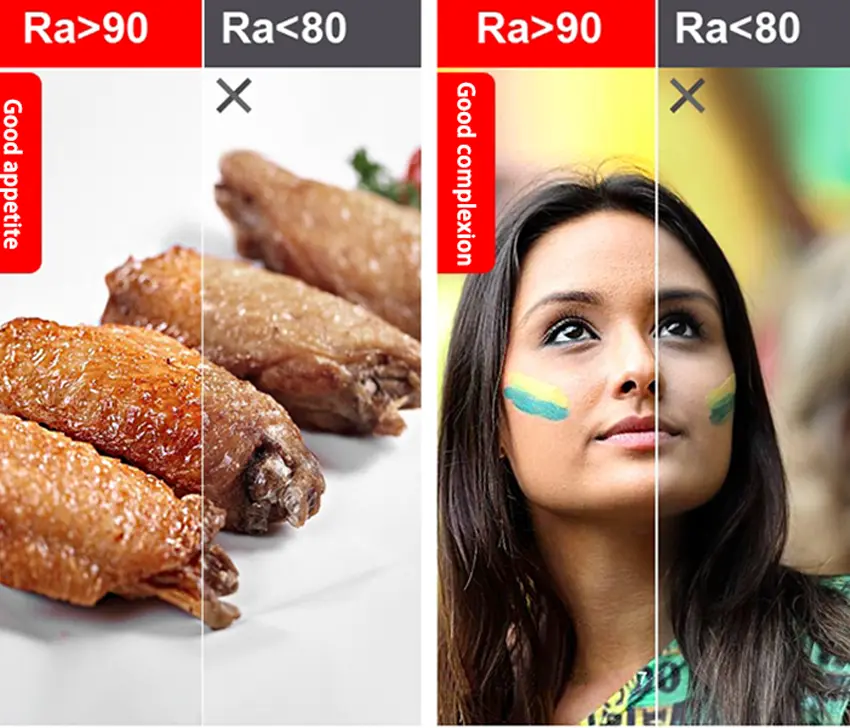

High CRI

COB LED strips offer High color rendering, with a CRI (Color Rendering Index) often exceeding CRI 90.

Dot Free

Another prominent advantage of COB LED strips is their high light density and High brightness. Each meter of the strip can accommodate up to 480 LED chips and above. This high-density arrangement not only increases the brightness output per unit length but also ensures that even if individual chips fail, it does not significantly affect the overall performance of the strip. The high light density makes COB LED strips an ideal choice for applications requiring high brightness, such as kitchen countertop lighting, cove lighting or step lighting in indoor environments.

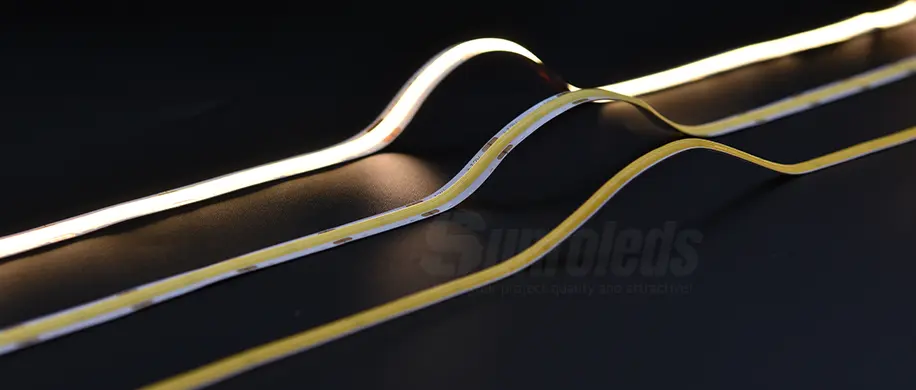

High Flexibility

The High Flexibility is a unique feature of COB LED Strips. The bending of the PCB will not damage the encapsulated LED

Wide Viewing Angle

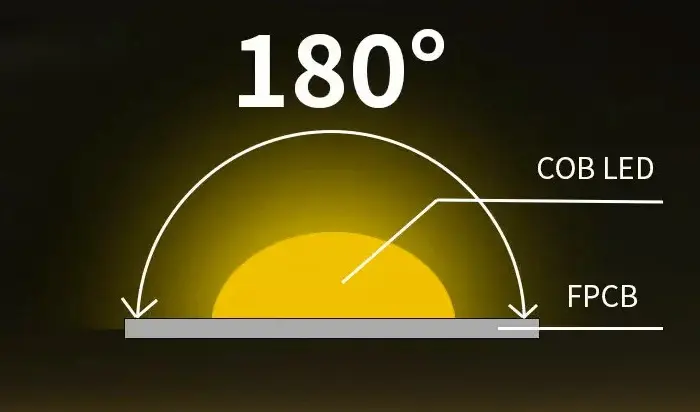

COB LED strips typically offer a wide beam angle of 180 degrees, ensuring that light is distributed broadly and

Excellent Heat Dissipation System

The superior heat dissipation performance of COB technology is another significant advantage. Since the LED chips are directly mounted on the substrate, heat can be more effectively dissipated, which not only improves the strip’s efficiency but also extends its lifespan. Effective heat management allows COB LED strip lights to operate stably at higher brightness levels for extended periods without encountering overheating issues.

What Are the Disadvantages of COB LED Strips?

Inconsistent Color Without Binning

One significant disadvantage of COB LED strips is the difficulty in maintaining color consistency across different batches, as they do not undergo the binning process commonly used in LED manufacturing. This lack of binning can result in slight variations in color temperature and hue, which become noticeable when integrating new segments into existing setups.

However, As technology development, our COB LED Strip Series maintains an SDCM (Standard Deviation of Color Matching) of less than 3 to ensure color consistency and avoid this issue.

Lower Light Efficiency

Compared to some high-power traditional LED strips, COB LED strips may have lower light efficiency. Our high-quality COB LED strips can reach up to 100Lm/W, but they do not achieve the 190Lm/W same as our 2835 LED strip Series. They often produce less light per watt of energy consumed, which can be a drawback for applications requiring high light output. However, many users find that the superior light quality and uniformity provided by COB strips outweigh this limitation.

Higher Production Costs

The production of High quality COB strips is generally more expensive than traditional SMD strips. This is due to the precise manufacturing processes and additional materials required for it. As a result, COB strips tend to be less accessible for budget-sensitive projects, limiting their market potential compared to lower-cost alternatives

Which is Better: COB LED Strips or SMD LED Strips?

In our view, there is no absolute “better” option, only what is more suitable for particular requirements. If you are looking for high uniformity, soft light effects, and have a higher budget, COB LED strips might be the better choice. On the other hand, if the budget is Top consideration and uniformity is less critical, SMD LED strips could be a suitable option. Ultimately, it depends on the project budget’s requirements and Light effect demands.

| Item/Difference | COB LED Strips | SMD LED Strips |

|---|---|---|

| Technology | Chip on Board Technology | Surface Mounted Device |

| Light output | Dot Free | Show Visible Individual light point |

| Max Light Efficiency | 100-120Lm/W | 190Lm/W |

| Beam angle | 180° | 120° |

| Heat management | heat dissipat fast | worse than COB LED strips’ |

| Cost consideration | a little higher | Cost-effective |

Are COB LED Strips Waterproof?

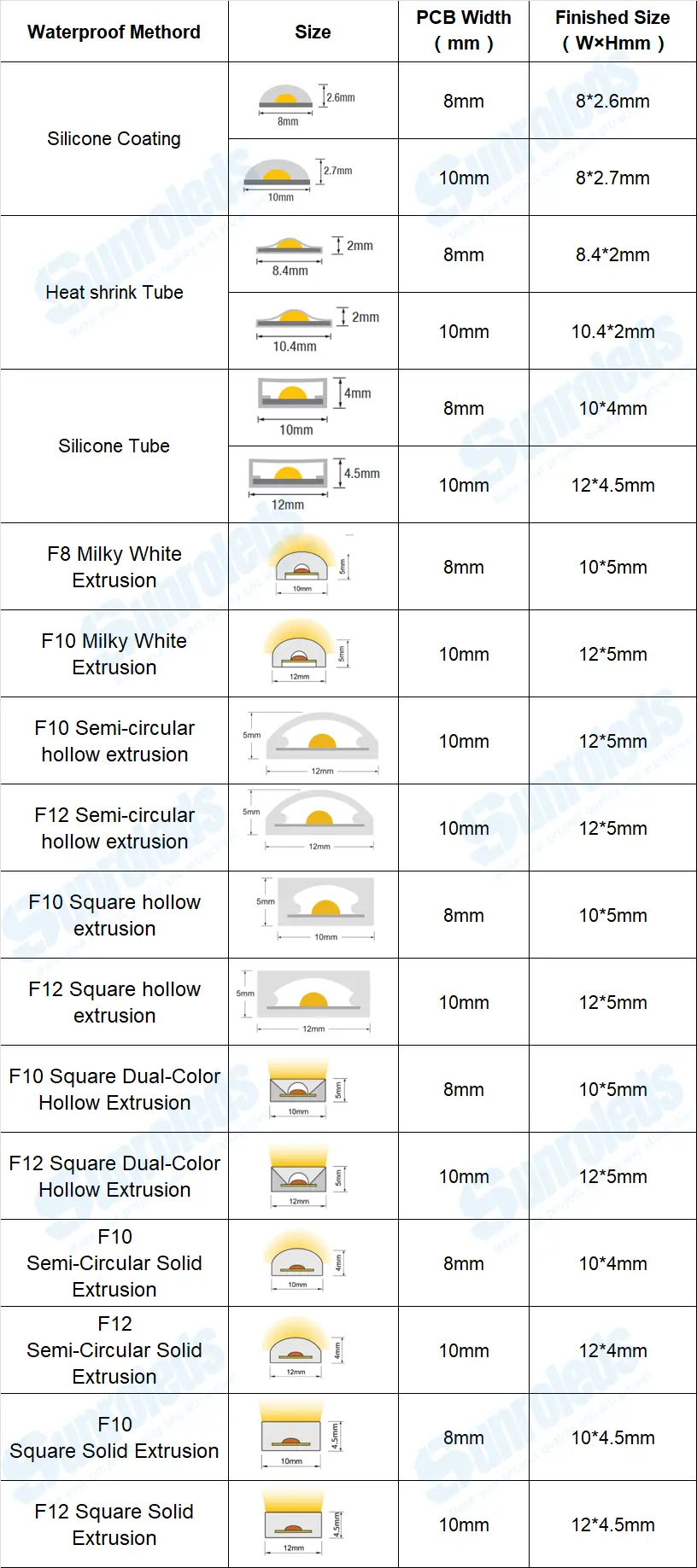

COB LED strips can be waterproof, but it depends on their specific design and Dimension. Generally, COB LED strips are available in various protection ratings:

- Non-Waterproof (IP20): These COB LED strips are designed for indoor use only and should be kept away from moisture and wet conditions.

- Waterproof (IP65, IP67, IP68): Waterproof COB LED strips come with different levels of protection:

- IP65: Protected against water jets from any direction, suitable for damp environments.

- IP67: Protected against temporary immersion in water up to 1 meter, suitable for more exposed outdoor applications.

- IP68: Fully protected against continuous immersion in water, ideal for applications requiring the highest level of waterproofing.

When choosing a COB LED strip for outdoor or wet environments, ensure you select one with the appropriate IP rating to match the intended application. Always verify the product specifications and consult with the manufacturer or supplier if you have specific requirements.

As professional LED Strip manufacturer, We have more following waterproof types but above for your options

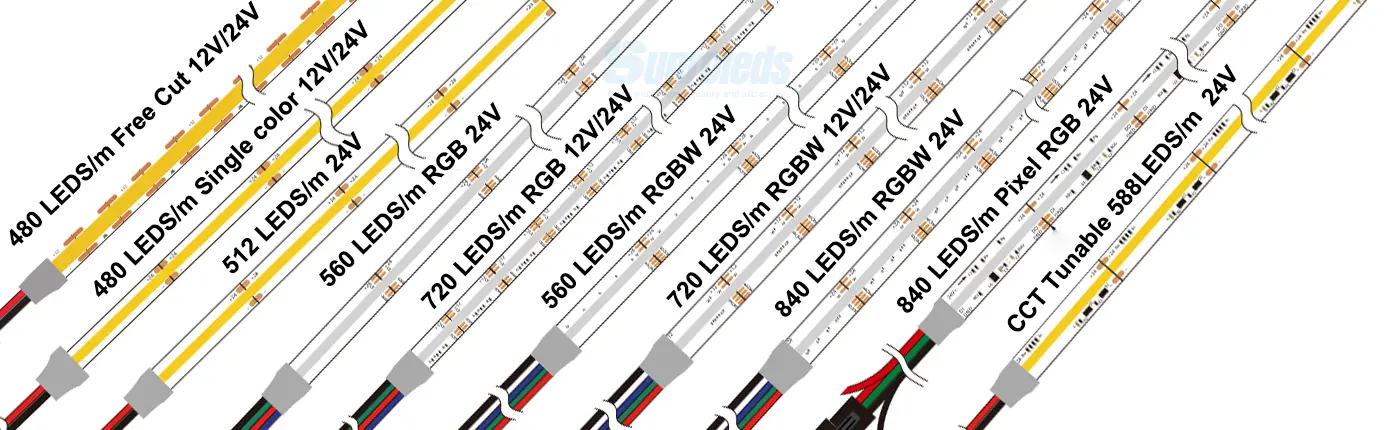

What are different types of COB LED Tape Light?

This is the most basic type of COB LED strips, designed to emit a single color of light. They are suitable for creating specific atmospheres or providing basic lighting, with common colors including warm white, cool white, and daylight,Blue, Green, Red, Yellow,Orange, Tiffany Blue,Marrs Green, and Plastic Pink.

This type of strip allows for adjustable Color Temperature (CCT), ranging from warm white to cool white. This feature makes them suitable for environments that require flexible adjustment of lighting color temperature, such as workspaces or multifunctional rooms.

RGB COB LED strips can produce multiple colors by mixing red, green, and blue primary colors. This type is suitable for creating dynamic lighting effects, often used in entertainment venues, stage performances, or spaces that require changing atmospheres.

RGBW strips add a white light chip to the RGB base. These advanced strips offer maximum color control flexibility, suitable for professional applications requiring precise color management.

This advanced COB LED strip Tapes allows for individual control of each segment on the strip, enabling complex lighting effects and animations. They are often used in creative lighting designs and interactive installations.

Designed for applications requiring long-distance continuous lighting, these strips can provide extended seamless light. They are ideal for large architectural projects, long corridors, or extensive outdoor lighting.

Custom-cuttable COB LED strips are designed to be cut at anywhere you need, offering more flexibility to fit different length requirements. This type is perfect for applications needing custom lengths, such as home decor or personalized projects.

How to Choose the Right COB LED Strips?

Light Efficiency and Brightness Check

High-quality COB LED strips typically have higher luminous efficiency >100Lm/W and high brightness. At the same power, the brightness of a high-quality strip will be significantly higher than that of a low-quality product. You can preliminarily judge the quality by comparing the brightness of different strips at the same power.

Color Evaluation

High-quality COB LED strips have stronger color rendering capabilities. you could judge the color quality if strip light are natural. Normally High-quality strips usually have a higher Color Rendering Index (CRI>90/95), accurately presenting the true colors of objects.

Uniformity Observation

Carefully observe the uniformity of the strip’s light output. High-quality COB LED strips should maintain consistent brightness and color temperature along their entire length, without obvious brightness inconsistencies or color differences.Generally speaking, the SDCM data is <3

PCB Material Evaluation

Check the substrate material of the strip. High-quality COB LED strips may use high conductivity FPC, The Best FPC Material quality is Polyimide with Rolled Cooper Roil,High conductivity. 2 ounce double sided Cooper FPC. These materials can help with better heat dissipation and stable performance.

Price Comparision

Although price is not the only indicator, the cost of high-quality COB LED strips is usually higher than that of low-quality products. An excessively low price may indicate compromises in materials or workmanship.

LED Chip Brand Vertification

COB Chip is the cord of Strip quality. Check the product’s brand information and certification marks. High quality COB Chip integrated advance encapsulation technology and quality Phosphor material. It can improve light effieicny and excellent colors, good heat dissipation and longer working life.

Professional Testing Equipment

If possible, use professional equipment such as spectrometers or colorimeters to measure the strip’s spectral distribution, color temperature, and CRI. These data can more accurately reflect the quality of the strip

How to Install COB LED Strips?

The installation of COB LED strips is relatively simple and can achieve an aesthetically pleasing lighting effect by following these steps.

Prepation

Before starting the installation, gather all necessary materials and tools. This includes COB LED strips, a power adapter, a controller (if needed), and auxiliary tools such as scissors, tape, or mounting clips.

Measurement and Planning

First, measure the required length of the strip according to the installation environment. Plan the installation location and route of the strip based on the actual situation on-site. This step is crucial for ensuring the aesthetic and functional outcome of the installation.

Cutting the Strip

If you need to adjust the strip length, cut along the marked cutting lines on the COB LED strip. Be careful to cut only at the designated locations to avoid damaging the strip.

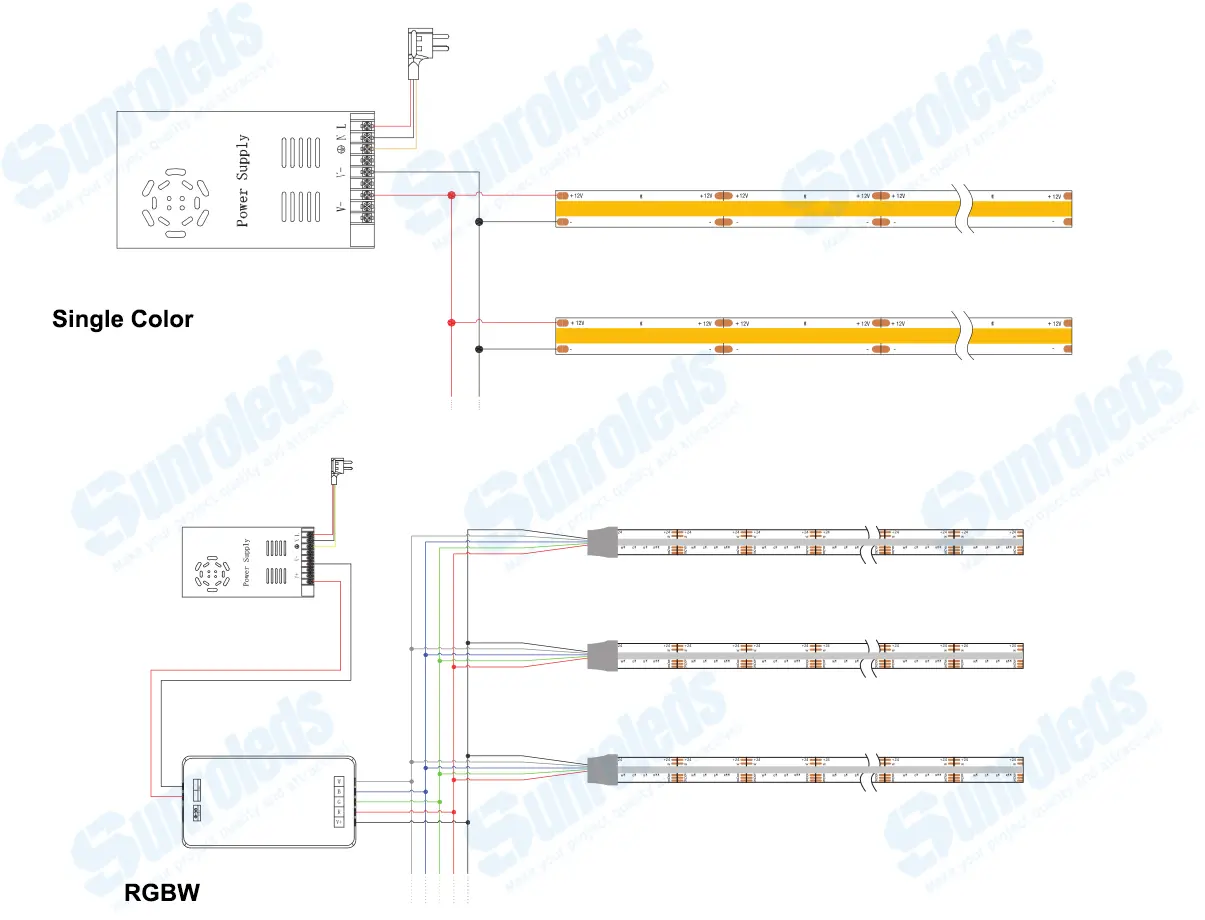

Connect to Power

COB LED strips usually require DC power. Choose a suitable power adapter based on the strip’s specifications, with common voltages being 5V, 12V, and 24V. Ensure the power supply’s wattage is sufficient to support the entire length of the strip.

Installing the Strip

Choose an appropriate installation method. You can use mounting clips to secure the strip in place or use the double-sided tape on the back of the strip to stick it directly. For areas requiring curved installation, be careful not to exceed the strip’s minimum bending radius to avoid damaging the internal circuitry.

Connecting the Controller (Optional)

If you are using RGB or dimmable COB LED strips, you will need to install a corresponding controller. The controller is usually connected between the power supply and the strip to adjust the strip’s color or brightness.

Paying Attention to Connection Distance

During installation, pay attention to the connection distance between COB LED strips. Typically, the maximum length of a single connection should not exceed 20 meters to avoid voltage drop causing uneven brightness or overheating issues.

Testing and Adjusting

After completing the installation, turn on the power to test. Check if the strip works normally and if the color and brightness meet your expectations. If any issues are found, promptly adjust the connections or replace problematic parts.

Maintenance Tips

Regularly check the working condition of the COB LED strip, ensuring solid connections and good heat dissipation. If cleaning is needed, disconnect the power first and gently wipe with a dry soft cloth, avoiding liquid cleaners.

By following these steps, you can successfully install COB LED strips and add beautiful lighting to your space. Remember, if you encounter any questions or difficulties during installation, it is best to consult a professional or refer to the product manual to ensure safety and effectiveness.

What Are the Common Applications of COB LED Strips?

Indoor Decorative Lighting

COB LED strips are popular for indoor decorative lighting in both residential and commercial spaces due to their uniform light output and flexible installation options. They can be used for ceiling contour lighting, wall corner accents, bookshelf backlighting, and more, creating a cozy, warm ambiance or a modern, stylish atmosphere.

Commercial Display Lighting

Retail stores, exhibition halls, and museums often choose COB LED strips to highlight displays. Their high color rendering index (CRI) and even light distribution ensure that products or artworks are presented in the best possible light, capturing the attention of customers and visitors.

Architectural Lighting

In the field of architectural lighting, COB LED strips have a wide range of applications. They can outline building contours, accentuate architectural features, or create dynamic lighting effects, adding unique nighttime appeal to structures. The flexibility of the strips allows them to adapt to various architectural forms, from modern minimalist designs to classical complex structures.

Workspace Lighting

In offices, studios, or kitchens where high-quality task lighting is essential, COB LED strips provide high brightness and even light distribution. They can be installed under workbenches or cabinets to offer shadow-free lighting, reducing eye strain and improving work efficiency.

Automotive Interior Lighting

Automotive manufacturers increasingly use COB LED strips to enhance the ambiance and functionality of vehicle interiors. The strips can be installed around dashboards, door panels, or under seats, not only improving the aesthetic appeal but also increasing safety during night driving.

Stage and Entertainment Lighting

For stage performances and entertainment venues, the high brightness and adjustable color temperature of COB LED strips make them an ideal lighting choice. They can create dynamic lighting effects, enhancing the visual impact of performances. Additionally, their low heat output ensures that performers remain comfortable.

Conclusion

COB LED strip technology proves a significant leap forward in the field of lighting. They offer efficiency, brightness, and uniformity that traditional LED strips can hardly match. By combining high light density, uniform light output, flexibility, and energy efficiency, COB LED strips provide innovative solutions for a wide range of lighting applications. From home decor to commercial displays, from architectural lighting to professional workspaces, COB LED strips demonstrate their unique advantages.

With continuous technological innovation and the emergence of creative applications, COB LED strips will undoubtedly play an increasingly important role in the future lighting market. They not only provide designers and consumers with more creative possibilities but also contribute significantly to establishing more energy-efficient and environmentally friendly lighting environments.

When selecting and using COB LED strips, it is crucial to consider specific application needs, installation environments, and control requirements. As the demand for high-quality, high-efficiency lighting solutions grows, COB LED strip technology will continue to evolve and improve, bringing more light and innovation to our living and working environments.

Share this article

Written by : Sophia Ng

Hey there! This is Sophia Ng, Worked for Sunroleds with 15 years in the industry, specializing in sales and marketing.

I'm committed to excellence and always aim to exceed expectations. Outside of work, I enjoy traveling and exploring traditional Chinese culture.

Let's connect and make some magic happen!