3 Key Factors Influencing the LED Strip Tape

In European regions, the issue of adhesive 3M tape on LED light strips often arises during winter in various projects. They have approached us with concerns the efficacy of the original 3M tape and seek solutions.

If you want to improve the usability of LED Light Strips and your material, then read on for your LED Strip Tape application.

Understanding LED Strip tape will help you choose the best type of tape for your project and improve the effectiveness of your build.

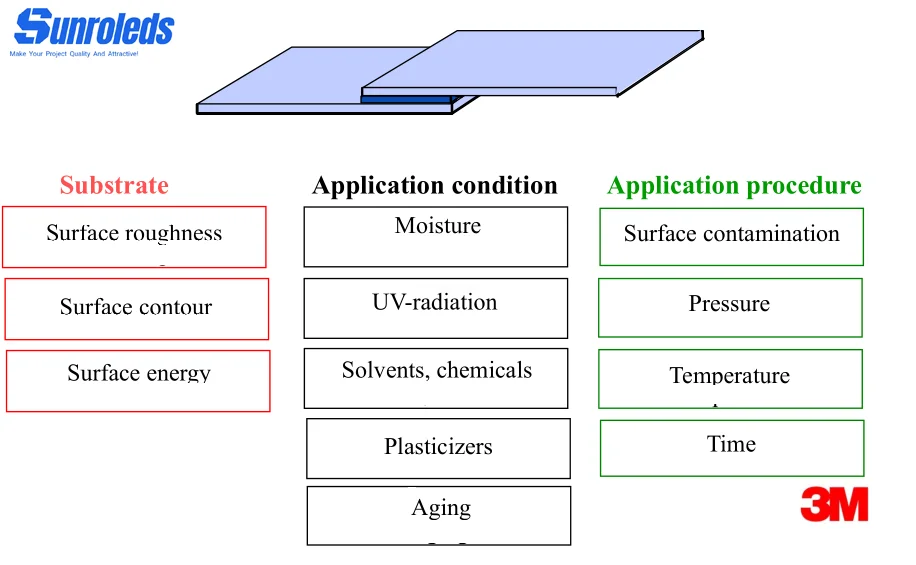

Influencing factors of LED Strip Tape

Factors affecting the use of 3M tape can be categorized into several aspects, including environmental conditions, surface materials, application Procedure, and duration of use. Here are some key factors

types of tapes such as double-sided tape, single-sided tape, electrical tape, etc., each with specific usage conditions and applications.

In summary, factors affecting the use of LED Strip adhesive tape are multifaceted. It is necessary to select the appropriate type of tape based on specific application scenarios and requirements, and pay attention to environmental conditions, surface treatment, and usage methods to ensure effective adhesion and longevity.

Surface Conditions

- Surface Roughness:

Generally Speaking, the rougher the surface, the poorer the adhesion of the 3M tape.

Rough surfaces result in irregular and uneven contact between the 3M tape and the surface, potentially leading to gaps or voids where effective adhesion cannot form, lowering the contact density between them, thus weakening the tape’s adhesive strength.

Therefore, to achieve optimal adhesion, it’s essential to choose smooth surfaces whenever possible and ensure proper cleaning and preparation of the surface before applying 3M tape to minimize the adverse effects of surface roughness on adhesive performance.

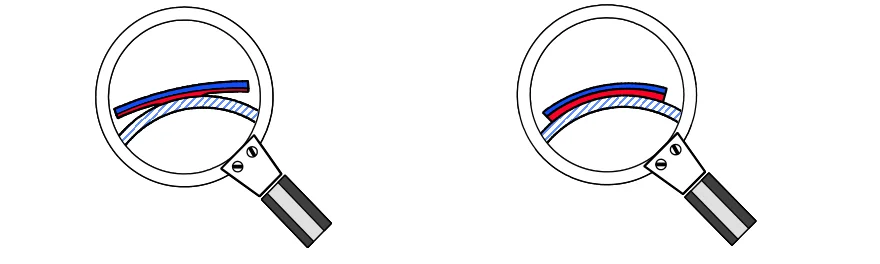

- Surface Contour

1. Surface Conditions

- Surface Roughness:

Generally Speaking, the rougher the surface, the poorer the adhesion of the 3M tape.

Rough surfaces result in irregular and uneven contact between the 3M tape and the surface, potentially leading to gaps or voids where effective adhesion cannot form, lowering the contact density between them, thus weakening the tape’s adhesive strength.

Therefore, to achieve optimal adhesion, it’s essential to choose smooth surfaces whenever possible and ensure proper cleaning and preparation of the surface before applying 3M tape to minimize the adverse effects of surface roughness on adhesive performance.

- Surface Contour

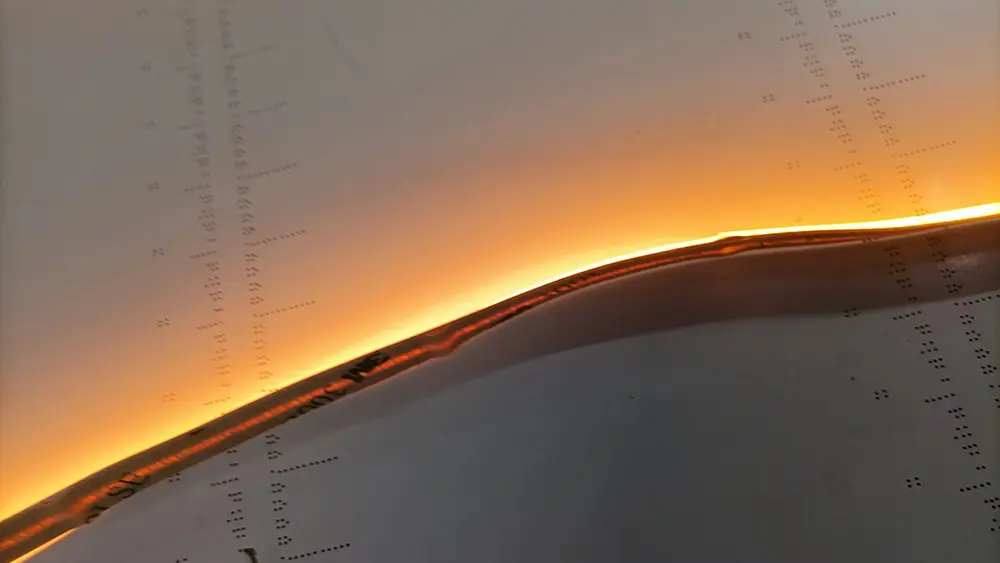

On surfaces with larger curvature, the 3M adhesive tape has bad adaptability and may experience higher stress, leading to stretching or deformation, which can affect its adhesive performance and durability.

Therefore, when using 3M adhesive tape, it is important to consider the surface curvature and choose the appropriate tape type and application method to ensure effective adhesion and long-term fixation on the surface.

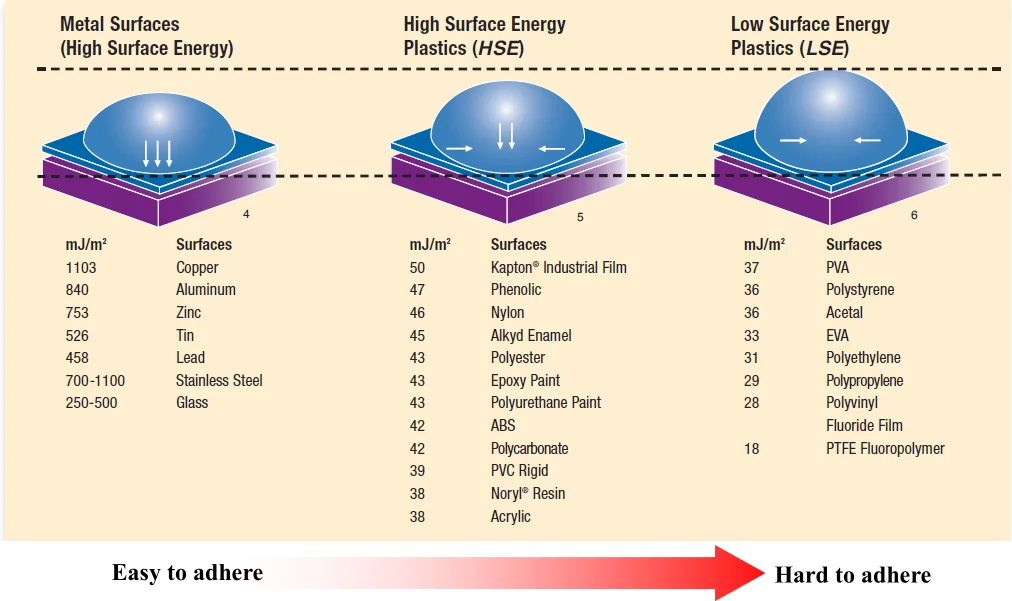

- Surface Material/Surface Energy

Some surface materials (such as glass, metal, plastic, Wooden etc.) are easy to adhere. but some materials are hard to adhere and may require special types of tape.

Environmental Conditions:

- Humidity

A humid environment can impact the adhesive properties, especially

for tapes not resistant to water. High humidity may prevent the adhesive from fully curing on the surface or isolate it from the substrate upon contact, thereby reducing adhesion. Additionally, humidity can cause corrosion or damage between the adhesive and the substrate.

- Ultraviolet (UV) Light:

Prolonged exposure to UV light can cause aging and degradation of the adhesive in 3M tape, leading to a decrease in its adhesive properties. UV light breaks chemical bonds within the adhesive, causing it to lose its adhesion ability. This effect can be more pronounced, especially in outdoor environments.

- Solvents

Exposure to solvents can degrade the adhesive properties of 3M tapes. Solvents can dissolve or soften the adhesive, leading to loss of adhesion or even complete failure of the bond. It’s important to avoid contact with solvents that may be present in cleaning agents or other chemicals.

- Plasticizers

Plasticizers are commonly found in certain materials, such as plastics and rubbers. These substances can migrate over time and interact with the adhesive, causing it to soften or weaken. This can result in a loss of adhesion or reduced performance of the tape.

- Aging

Over time, 3M adhesives may undergo aging, which can be accelerated by factors such as exposure to heat, light, or oxygen. Aging can lead to changes in the adhesive’s properties, such as decreased tackiness or reduced cohesive strength, ultimately affecting its performance.

To mitigate these effects, it’s important to store and use 3M tapes in conditions that minimize exposure to humid or strongly UV-lit environments, solvents, plasticizers, and factors that accelerate aging, such as high temperatures and prolonged exposure to sunlight. Additionally, selecting tapes with formulations designed to resist these factors can help maintain adhesive performance over time.

Application Methods

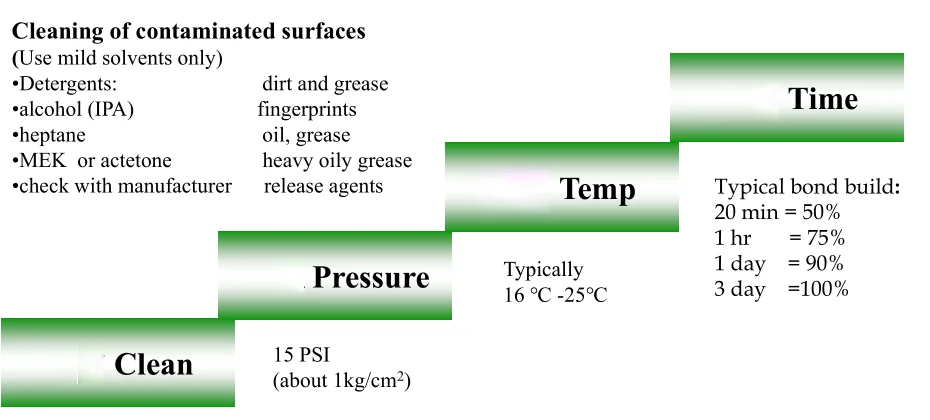

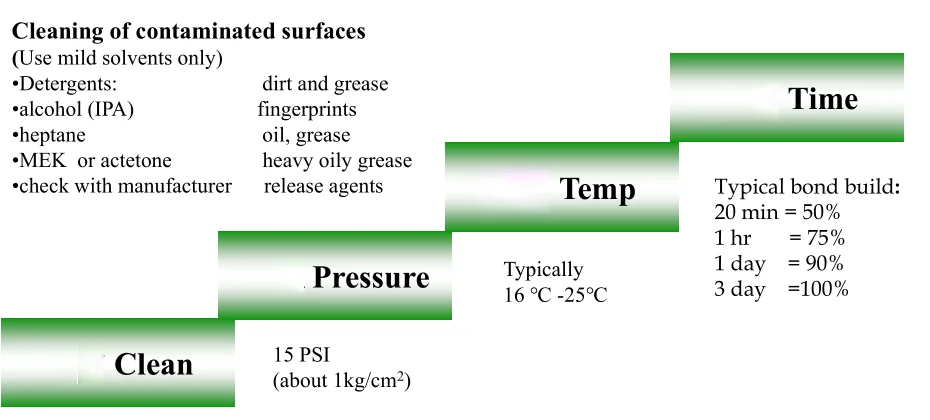

- Temperature

3M tape is sensitive to temperature, and excessively high or low temperatures may affect its adhesive strength and durability.

Generally, higher temperatures may enhance the tape’s adhesive strength, while lower temperatures may weaken it. This is because at higher temperatures, the adhesive in the tape becomes softer and more tacky, making it easier to make contact with the surface and form a durable bond.

At lower temperatures, the surface may become more brittle or have frost, which could affect the tape’s adhesive effectiveness. Therefore, it’s advisable to ensure the surface is dry, clean, and installed at suitable temperature conditions before applying 300LSE tape.

16-25° is the optimal temperature range for 3M adhesive mounting. It cannot be used at 200℃. after mounting. The highest operating ambient temperature given by 3M is 148℃, and it is for short-term application, and the highest temperature is for long-term application. The temperature does not exceed 93℃.

temperature is a crucial factor affecting the adhesive performance of 300LSE tape, with the suitable temperature range. However, in practical use, considerations should also be given to the effects of temperature on tape aging and degradation, and appropriate surface preparation should be conducted before installation.

- Cleaness

The LED Strip tape requires a clean, dust-free, and grease-free surface for proper adhesion; otherwise, it may affect its adhesive strength.

- Pressure

Applying appropriate pressure during tape application can help it adhere better to the surface.

- Duration of Use

Prolonged use may cause the adhesive strength of the tape to weaken or even fail.

Conclusion

3M Tape Company produces various types of tapes such as double-sided tape, single-sided tape, electrical tape, etc., each with specific usage conditions and applications.

In summary, factors affecting the use of LED Strip adhesive tape are multifaceted. It is necessary to select the appropriate type of tape based on specific application scenarios and requirements, and pay attention to environmental conditions, surface treatment, and usage methods to ensure effective adhesion and longevity.

Share this article

Contact us Now

Written by : Sophia Ng

Hey there! This is Sophia Ng, Worked for Sunroleds with 15 years in the industry, specializing in sales and marketing.

I'm committed to excellence and always aim to exceed expectations. Outside of work, I enjoy traveling and exploring traditional Chinese culture.

Let's connect and make some magic happen!

Follow us

A quick overview of the topics covered in this article.

Latest articles

July 27, 2024

July 27, 2024

July 27, 2024

July 27, 2024